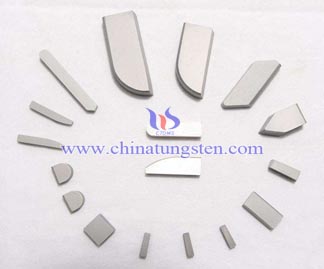

Tungsten Carbide Blades Manufacturing Process

Sintered tungsten carbide blades after forming,the following is tungsten carbide blades manufacturing process:

1)The crushed very fine tungsten carbide powder and cobalt powder by pressing the desired shape, then the metal particles are connected to each other, but the combination was not very close, just a little by the point of the force will be crushed.

2)The powder particles have been formed with the block temperature, the drying degree of the connection Bo gradually at 700-800 ℃ when combined with the fragility of the particles, the gap between the particles is called pores.

3)The heating temperature increased to 900 ~ 1000 ℃, the voids between the particles is reduced, the black portion of a line shape almost disappeared, leaving only a black portion in particular block.

4)The temperature was slowly approaching 1100 ~ 1300 ℃ (i.e., the usual sintering temperature), the air gap is further reduced binding between the particles becomes more robust.

5)When the sintering process is completed, the blade was small polygonal WC particles, around which the white matter can be seen, that is the diamond. Blade organization sintering is completed drilling basement, covered with tungsten carbide particles. Particle size, shape, and layer thickness of the drill is different, the nature of the tungsten carbide inserts are also different.