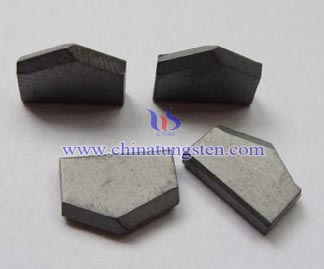

Tungsten Carbide Cutting Blades

Tungsten carbide blades all man-made products with the same ingredients, manufacturing tungsten carbide cutting inserts should first solve the problem of raw materials, namely to determine the composition of blades materials and formulations. Most blades are now made of cemented carbide, the main component of tungsten carbide (WC) and cobalt (Co). WC is the hard particles in the blade, and Co as the binding agent can blades molding.

|

Determine the particle size, composition and other technical parameters of raw materials, you can start cutting blades actual manufacturing processes. First, in line with the ratio of tungsten powder, carbon powder and cobalt powder into a large size and a washing machine almost mill, the addition of alcohol and water, powder milling process, prepare a thick black slurry . This slurry is then placed in a cyclone dryer in the future will be one of the liquid evaporates, you get a slug of powder, and stored. |

The next step in the preparation process, you can get blades shape. First, the powder is prepared with polyethylene glycol (PEG) mixing, PEG as a plasticizer, the powder can be temporarily bonded together as dough. Then press molding to obtain the material is pressed in the die blank, which was placed in a large sintering furnace, sintered at high temperatures. In the sintering process, PEG melted mixture is discharged from a preform, and finally left semi-tungsten carbide blades. When the PEG is stripping blades shrink to its final size. This process step requires precise mathematical calculations since depending on the material composition and the ratio of the amount of shrinkage, the blade is different, and requires the control of dimensional tolerances of the finished product within a few micrometers. The shape of the blade is made. Depending on the blade press method, the press may be used for uniaxial pressing can also be used to suppress multi-axis machine from a different angle of blades shape.

Tungsten carbide cutting insert grades and performance:

| Grades | Equivalent to ISO grouping code |

Density g/cm3 | Flexural strength MPa |

Hardness HRA | Uses |

| YT15 | P10 | 11.3 | 1300 | 91 | For steel, cast steel finishing and semi-finishing, should adopt a medium feed rate and higher cutting speed. |

| YT05 | 12.6 | 1260 | 92.5 | ||

| YC201 | P20 | 11.79 | 1400 | 91.8 | For steel, cast steel finishing and semi-finishing, should adopt a medium amount of feed, YS25 dedicated to steel, cast steel milling. |

| YT14 | 11.4 | 1400 | 90.5 | ||

| YS25 | 13.0 | 1780 | 90.5 | ||

| YT5 | P30 | 12.8 | 1570 | 89.5 | For steel, cast steel heavy cutting, poor job conditions, the low-speed large amount of feed roughing. |

| YC45 | P40 | 12.75 | 2250 | 90 | For steel, cast gravity cutting, cutting parameters can be large, but also for face milling. |

| YS8 | M05 | 13.9 | 1720 | 92.5 | Applicable to iron-based, nickel-based superalloy, the degree of strength steel finishing, also applies to chilled cast iron, heat-resistant stainless steel, high manganese steel, hardened steel finishing. |

| YW3 | M10 | 12.9 | 1390 | 92 | For stainless steel, alloy steel ordinary finishing and semi-finishing. |

| YW1 | 13 | 1290 | 91.5 | ||

| YN201 | M20 | 13.9 | 1600 | 93.0 | For stainless steel, low alloy steel semi-finishing. |

| YS2T | 14.4 | 1960 | 91.5 | ||

| YW2 | 12.9 | 1460 | 90.5 | ||

| YM30 | M30 | 14.5 | 2000 | 91.5 | Suitable for heat-resistant alloys roughing. |

| YG3X | K05 | 15.1 | 1300 | 91.5 | For cast iron, non-ferrous metal finishing. |

| YG3 | 15.0 | 1300 | 90.5 | ||

| YM201 | K10 | 13.9 | 1600 | 93.0 | For cast iron, non-ferrous metal finishing, semi-finishing, can also be used for manganese steel, hardened steel machining. |

| YG6X | 14.8 | 1560 | 91.0 | ||

| YD201 | K20 | 14.89 | 1800 | 91.0 | For cast iron, light alloy semi-finishing, roughing, also made of cast iron, low alloy steel milling. |

| YG6 | 14.9 | 1670 | 89.5 | ||

| YG8 | 14.6 | 1840 | 89 |