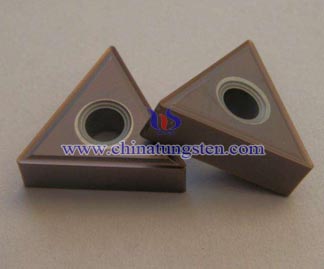

Tungsten Carbide CNC Blades

Tungsten carbide CNC blades is a modern metal cutting application areas mainstream products. Mainly used in metal turning, milling, cutting grooving, thread cutting and other fields. It is characterized by high efficiency, high wear than traditional welding blade, blade alloy processing efficiency improved by more than four-fold. As technology continues to progress coating, wear resistance, high temperature key technology breakthroughs will further improve efficiency and reduce processing costs.

Tungsten carbide CNC blades in the form of the workpiece surface are able to be divided into five categories:

1.Processing of various CNC blade outer surface, including turning, planing, milling cutters, outer surface broaches and rasp, etc.;

2.Hole machining CNC blade, including drills, reamers, boring tools, reamers and the inner surface broaches, etc.;

3.Thread processing CNC blade, including taps, dies, automatic opening and closing of the thread cutting head, thread turning and thread milling cutters;

4.Gear cutting CNC blades, including hobs, shaper cutters, shaving cutters, bevel gear cutting tools, etc.;

5.Cutting CNC blades, including tipped circular saw blades, band saw, bow saw, cutting tools and saw blades cutters and so on. In addition, there is a combination of tools.

By cutting movement and the corresponding shape of the blade,tungsten carbide CNC blades can be divided into three categories:

1.General CNC blade, such as turning, milling, planing (not including the forming tool, forming cutter and cutter), boring, drill, reamer, reamer and saws;

2.Forming CNC blade, the cutter blade and the machined workpiece cross section has the same or near the same shape, such as the forming tool, forming cutter, milling cutter, broach, taper reamer and various thread processing tool;

3.generating CNC blade is machined by method of generating gear tooth surface or similar workpieces, such as the hob, gear shaper, gear shaving cutter, bevel gear planer and bevel gear milling cutter etc.

Tungsten carbide CNC blades Compared with ordinary machine tools used, there are many different requirements, mainly has the following characteristics:

⑴Tungsten carbide CNC blades rigidity (especially roughing tool), high accuracy, low vibration and thermal distortion;

⑵Tungsten carbide CNC blades interchangeability for quick tool change;

⑶Tungsten carbide CNC blades life and high cutting performance stable and reliable;

⑷Tungsten carbide CNC blades dimensions for easy adjustment to reduce ATC adjustment time;

⑸Tungsten carbide CNC blades should be able to reliably breaker or volume shavings, chips facilitate exclusion;

⑹Tungsten carbide CNC blades serialization, standardization, in order to facilitate programming and tool management.